The Volvo Group has recently unveiled plans to establish a new heavy-duty truck manufacturing facility in Mexico. This initiative is set to complement its existing production operations in the U.S., aiming to bolster the growth trajectories of Volvo Trucks and Mack Trucks in the North American and Canadian markets, while also enhancing Mack Truck sales throughout Mexico and Latin America. Slated to commence operations by 2026, this expansion underscores the group’s commitment to meeting growing market demands.

Existing facilities, including the Mack LVO plant in Pennsylvania and the Volvo NRV plant in Virginia, will continue to serve as central production hubs for the company’s heavy trucks in North America.

The upcoming Mexican plant is projected to span approximately 1.7 million square feet, dedicated to manufacturing heavy-duty conventional vehicles under the Volvo and Mack brands. The facility will feature comprehensive assembly operations, including cab body-in-white production and painting.

This strategic expansion into Mexico is expected to streamline logistics, particularly for sales in the southwestern and western U.S. regions, as well as in Mexico and Latin America. It leverages a well-established supply and production ecosystem, enhancing the resilience and flexibility of Volvo’s North American industrial footprint, and setting the stage for continued growth and efficiency in operations.

During a recent gathering in Gothenburg, Sweden, it became evident that Volvo Trucks is not only focusing on the technological evolution of transport, but also on how these advancements can generate profitability amidst rising demands for sustainable practices. The company’s leadership, including Volvo Trucks President Roger Alm, emphasized the importance of transitioning to net-zero emissions by 2040, a movement initiated globally by the Volvo Group in 2019.

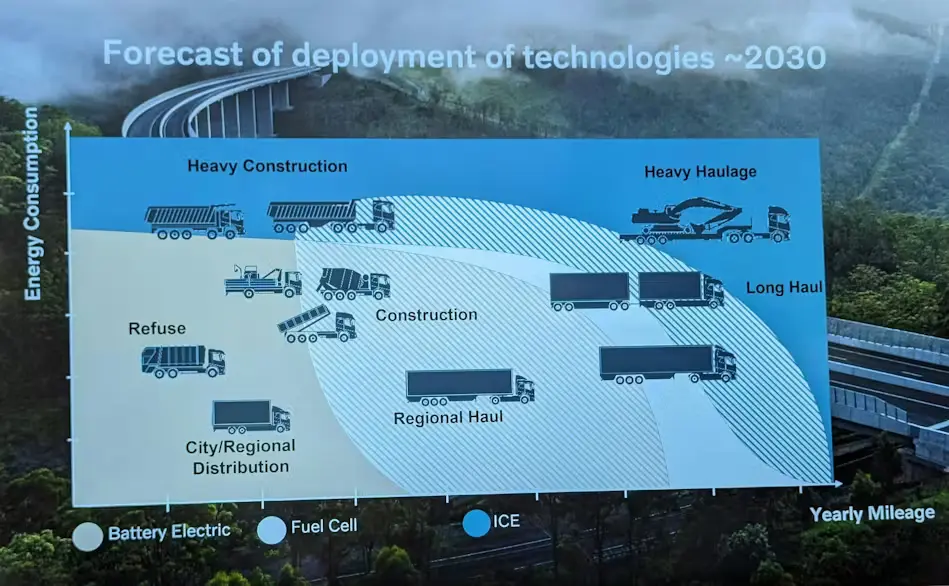

From a scenic conference room overlooking a bright Gothenburg skyline, Alm expressed the urgency of this transition, not just for the current climate but for the legacy left to future generations. He highlighted that while the specifics of which alternative powertrain systems will dominate are still unknown, Volvo is exploring all avenues—including battery-electric, fuel-cell electric, and renewable internal combustion engines.

The transition to greener technologies is likened to the shift from horse-drawn carriages to automobiles in the early 20th century, a transformation witnessed on New York’s Fifth Avenue over just fifteen years. Today, as the industry faces a similar overhaul, Volvo acknowledges the skepticism among North American fleet operators regarding the feasibility and profitability of zero-emission vehicles. Despite the challenges, Volvo remains optimistic about the adoption of green technologies, spurred by increasing demands from consumers and transport buyers for sustainable transportation solutions.

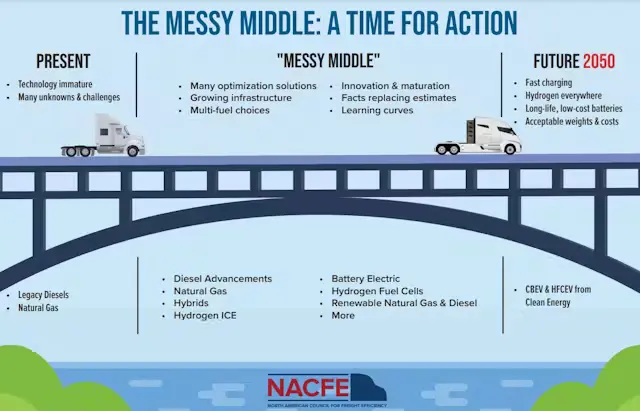

Addressing the financial concerns associated with green technology, Volvo’s executives argue that transitioning to environmentally friendly options is not only viable but potentially lucrative, especially for those willing to pioneer these changes. The North American Council for Freight Efficiency also notes that while the industry is currently in a transitional phase, known as the “Messy Middle”, the exploration of diverse fuel options is crucial for future sustainability.

The new technologies being tested and adopted by early adopters in the industry showcase potential scalability and profitability, enhancing business prospects for those at the forefront of this transformation. This approach not only benefits the environment but also promises to enhance the economic stability of the fleets involved, ultimately influencing consumer prices minimally while fostering a greener future.